For over 60 years, Industria Chimica Mediterranea is at the side of its customers offering ad hoc and timely solutions as well as products.

Constant renewal and growth were the principles that over the years have led to the development of our range

company profile

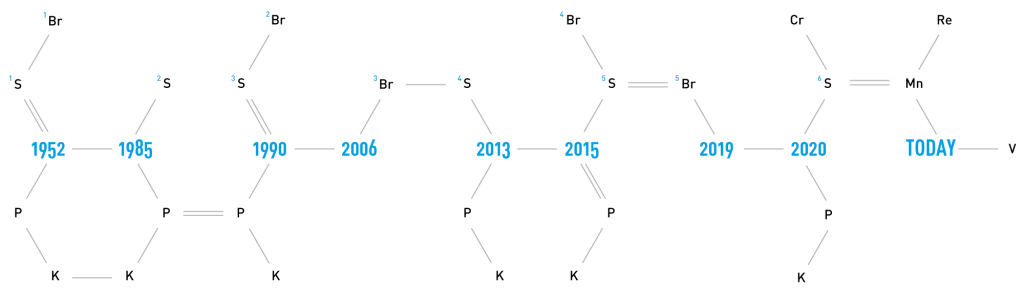

ICM molecular structure

The research and development department has identified the ICM molecule,

which is a stable, elastic and projected towards the future molecule.

MISSION

For over six decades ICM has been in contact with the varied manufacturing world, penetrating its needs and, above all, refining a great versatility aimed at solving the various operational needs.

This spirit of proximity to the customer is still alive today as an authentic corporate mission that is realized in the development of ad hoc products and materials in tune with the user’s request.

VISION

An eye to the past and one to the future. The strategy of the ICM can be summarized in these words in the firm belief that success is based on the reconciliation between tradition and innovation.

ICM is preparing to continue its activity in the third generation with a strong propensity for technological innovation and without abandoning its identity as a family business.

Research & development

ICM’s laboratory is equiped with new machineries for the characterization of the polymers and the analysis of their physical and mechanical properties such as:

- Analysisof thermal transitions of a polymer

- Determination of molecular structure

- Measure of mechanical properties

- Pilot productions

The activities developed consist of:

- Control of incoming raw materials

- Control of finished products

- Customer assistance

- Development of new products

Company policy

The development and continuous improvement of the management system is a precise and constant commitment for Industria Chimica Mediterranea.

The Company is firmly convinced that its policy has to create an harmonious work environment, where all employees enjoy the utmost trust and are appropriately responsibilized, in order to create the essential basis for obtaining full satisfaction of all interested parties: the satisfaction of customers’ requirements, respect for the environment and continuous improvement of the Environmental Management System.

With regard to the Environment, the company has currently achieved the GRS (‘Global Recycle Standard’) certification aimed at recognizing the use of recycled materials, and the ISO 14001: 2015 certification. These objectives are well defined and require the involvement of all human resources that are part of our company.

How to reach the goal

- increase the sense of responsibility towards the environment of all employees, who will be instructed and keep up to date by adequate training on the relevant environmental aspects;

- take measures to reduce the use of resources and to prevent impacts on the environment;

- take measures to prevent accidents and to remedy any damage caused to the environment from activities, products and services of the organization;

- cooperate with public authorities to ensure environmental protection;

- keep the dialogue with the clients, providing adequate information on the environmental impact of the organization’s activities;

- keep the dialogue with customers, providing adequate information on the methods of use and disposal of waste resulting from products and services provided by the organization.

- ensure that any subcontractors and its suppliers comply with the same environmental standards as the organization.

The company also undertakes to comply with the main conventions of the International Labor Organization (ILO), with national legislation and with the conditions provided for by national bargaining on the following points:

- Freedom of association and right to collective bargaining

- Child labor

- Health & Safety

- Prevention of any phenomenon of discrimination and abuse

- Regularity and transparency in employment contracts, registration of working hours, payment of wages due.

The organization is also very careful in handling complaints and is committed to maintaining the current corporate climate constant, in order to prevent the risk of harassment and bullying.

Industria Chimica Mediterranea also undertakes to provide the necessary technical, economic and professional resources, so that the objectives of its policy are fully achieved.

The organization guarantees, through subsequent verification activities, that this policy is understood and implemented and that the stated objectives are pursued.

Everyone is involved in achieving the goal in order to move toward a continuous improvement. Industria Chimica Mediterranea believes that achievement and maintenance of the ISO 14001 Environmental Certification will not be a point of arrival, but a fundamental step on its path.

This document represents the reference of the entire company management system, guides the organization of the system and identifies the operational directions towards which the company intends to move.

Green line

Industria Chimica Mediterranea Srl has joined the market momentum towards eco-sustainability by developing a line of materials with reduced environmental impact, through the use of recycled raw materials.

We have developed a reduced environmental impact line of materials for toe boxes and heel counters and supports for footwear and bags, selecting raw materials coming from renewable sources in order to reduce CO2 emission and save fossil sources.

Let’s talk about ecosustainability

The 3 categories of sustainable materials

RECYCLED

It is a process aimed for giving a second life to waste that can be reintroduced into production processes. The plastic used thus becomes a resource for the creation of further products.

BIOBASED

Renewability concerns the origin of the material. A renewable source material may be biodegradable but it is not necessarily so. If not, it can be recycled.

BIODEGRADABLE

Biodegradability concerns the end of life of the material. A biodegradable material does not necessarily have to come from renewable sources; it can also have a fossil origin.

Bioplastics pros

A breath of fresh air for the planet

A material produced using raw materials with low environmental impact offers a great advantage to the planet. It saves fossil resources and its production is less polluting.

Advantages of bio-polymers

-

SAVE FOSSIL RESOURCES

-

LESS CO2 EMISSIONS

-

REDUCED ENVIRONMENTAL IMPACT

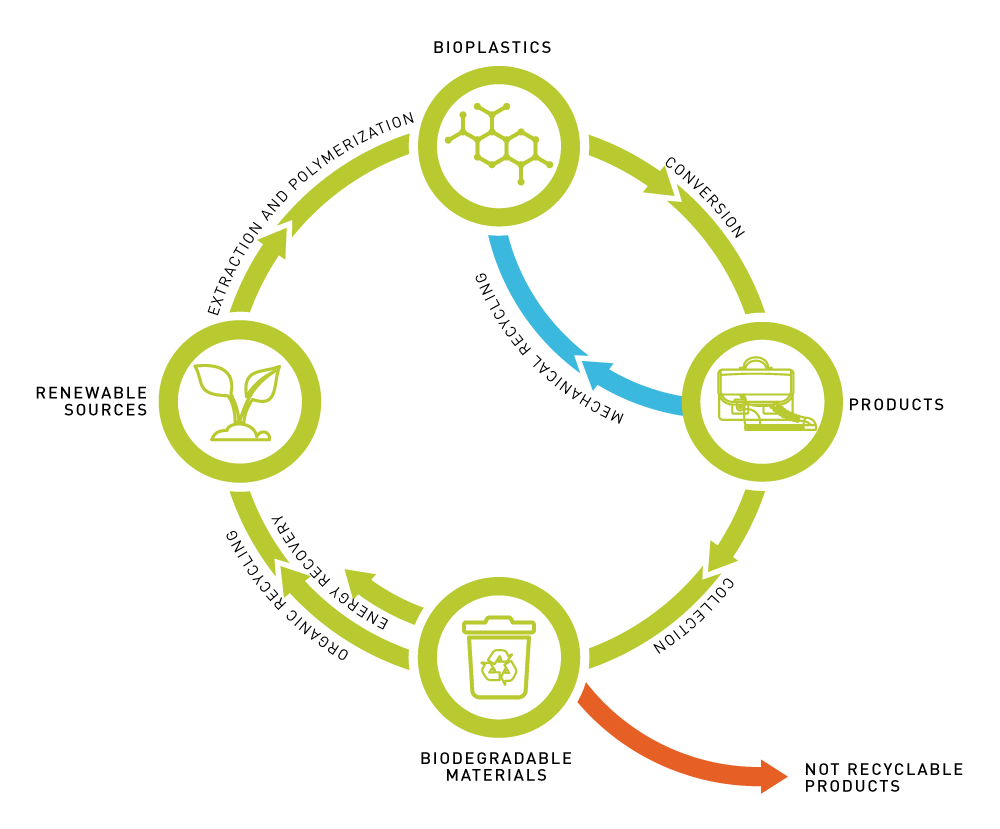

Life cycle of bioplastics

Synthetic scheme for a conscious choice of bioplastics

The diagram represents a summary of the life cycle of bioplastics.

In evidence the biodegradable and non-biodegradable materials that feed the cycle in a different way.

Non-biodegradable nor recyclable products do not feed the cycle and are destined for disposal.

What is the best choice

ICM’s strategy

There is no best choice.

Reclycling, where it is possible, would be certainly the preferable solution.

Using bio-based raw materials helps saving fossil resources and thus reduces greenhouse gas emissions. On the other hand it cannot be pushed to the point of deforestation or the subtraction of land destined to cultivation.

The utilization of biodegradable is not always compatible with the purpose of the product.

Therefore it will be the contemporaneous use of these three alternatives to reduce the environmental impact of industrial production.

FILM IN TPU

Strengt & Flexibility

NO TPU was harmed

in the making of this picture.

The TPU is the link between the thermoplastic polymers and rubbers.

With the firsts shares the ability to thermoform, due to heat, even after hardening; with the latters the elasticity. In other words, in the field of elastomers, it is the polymer with the best mechanical properties, excellent flexibility in the absence of plasticizers, even in the case of high hardness, as well as resistance to low temperatures, light, aging and bacterial attack.

The Industria Chimica Mediterranea transforms TPUs of different nature: aromatic polyethers and polyesters, for applications that need flexibility, strength and toughness, and aliphatic, where light stability, transparency and strong adhesion are required. The range of hardness varies from 60 to 98 Shore A, the thickness range goes from 100 to 1000 microns.

The manufacturing process of the Industria Chimica Mediterranea, which does not involve dissolution in solvent, but melting by heat, makes it a material with a low environmental impact, interesting for all those sectors where an extremely resistant, elastic and waterproof support is required.

karma

LINE OF ECO-SUSTAINABLE SUPPORTS IN TPU

TECHNICAL FEATURES

-

REDUCED ENVIRONMENTAL IMPACT

-

SOFT TOUCH

-

RESISTANCE TO OIL, GREASE AND DETERGENTS

-

LOW TEMPERATURE RESISTANCE

-

EXCELLENT MECHANICAL RESISTANCE

Toe puffs & counters

Toe puffs and counters are internal reinforcements that support the upper.

In other words they are the skeleton of the shoe.

cotton

extruded

For casual shoes and reinforcements for leather goods

NON-WOVEN FABRIC

Adhesives & Glues

Line of glues and adhesives for various uses and applications

wood

- polychloroprene solvent-based adhesives

- pvac and eva vinyl glues

- urea glues

- hot melt eva and tpu adhesives

- polyurethane adhesives

- epoxy-polyurethane adhesives

footwear

- polychloroprene solvent-based adhesives

- polyurethane solvent adhesives

- natural rubber solvent-base adhesives

- polychloroprene glues in aqueous dispersion

- natural rubber latex

- vinylacrylics and vinyls glues

- primers

UPHOLSTERY

- thermoplastic solvent-based adhesives

- polychloroprene water based bicomponent adhesives

- polychloroprene water based mono-component Simalfa® adhesives

- thermoforming adhesives based on eva

special application

- ad-hoc formulations for specific requests

- products for paper industry, boilers, laminations

- thermoacoustic insulation

TEam

our team is at your disposal

- Corso Protopisani, 138 - 80146 Napoli, ITA

- +39 0815591304

- +39 0817523380

- Write us an email

- connect with linkedin

- follow us on facebook

- follow us on Instagram